Fast and flexible

production planning

Speed

Create optimal plans in no time – no matter how often you need to reschedule.

Increase your delivery reliability with holistic and transparent production planning.

Delivery

reliability

Machine

utilization

Plan how to utilize your machines optimally and use the resources made available.

Reduce the number of set-up times and considerably shorten lead times as a result.

set-up times

A high number of alternatives, cross-dependencies and risks make production planning challenging.

Production planning and machine utilization are

demanding tasks. The range of options is huge and there are a lot of cross-dependencies and planning risks. As well as these, there are also goals which often conflict with one another.

Careful production planning therefore takes time and requires an experienced hand. If plans have to be changed at short notice, the quality of the planning inevitably suffers as a result. Furthermore, experienced planners are tied up with the day-to-day business so that a valuable resource for the strategic development of the planning process is unavailable.

Do you see optimization potential in your own

production planning? If any of the statements below sound familiar to you, then maybe we should discuss your problems together.

With the help of mathematical optimization to more delivery reliability with increased flexibility and efficiency at the same time.

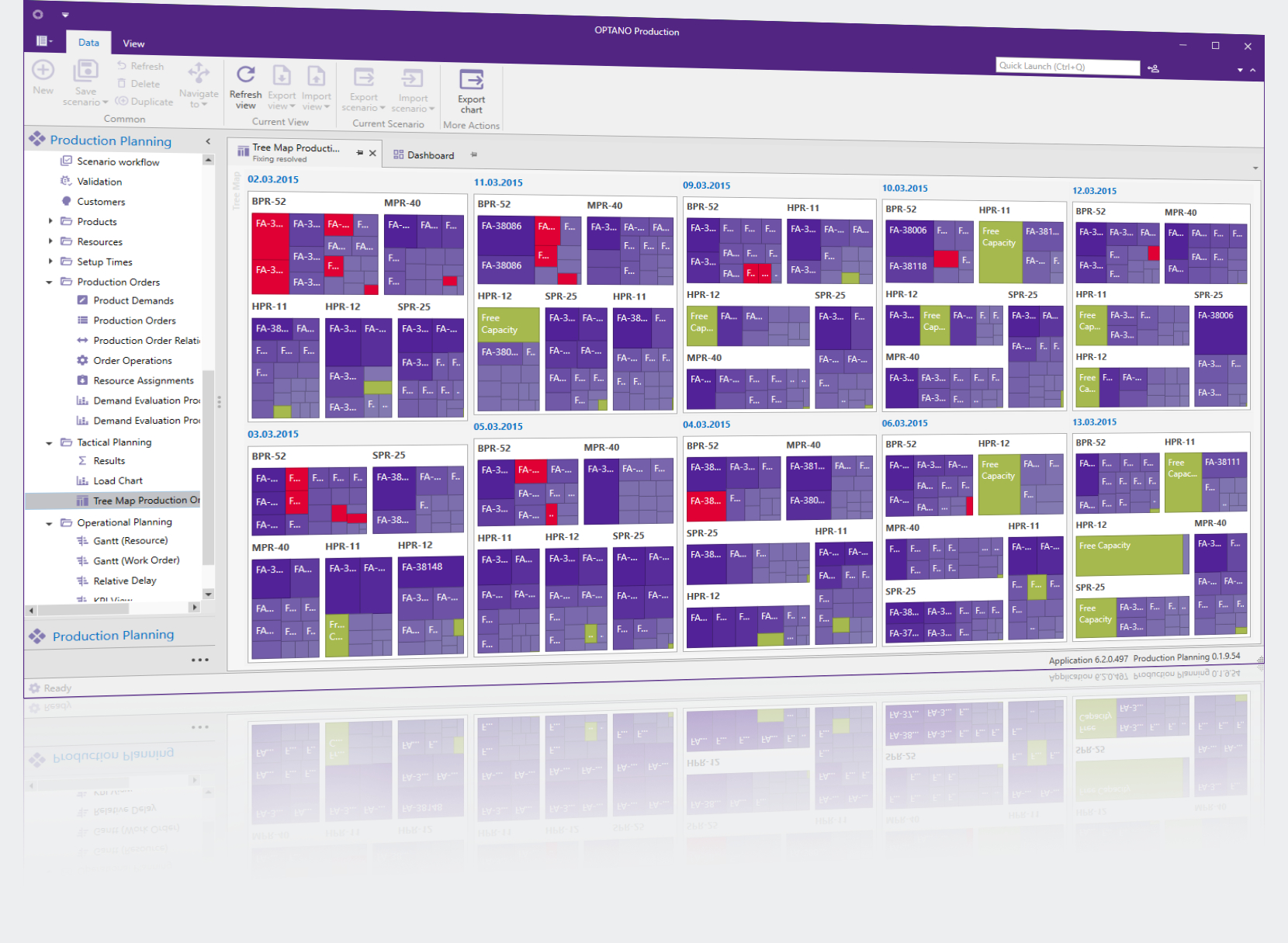

Benefit from easy planning, even when you have to make unexpected changes

OPTANO lets you create new production plans in an instant. The system calculates an alternative plan based on new parameters within a very short time and guarantees that the new planlety you achieve the optimum– no matter how often you have to reschedule.

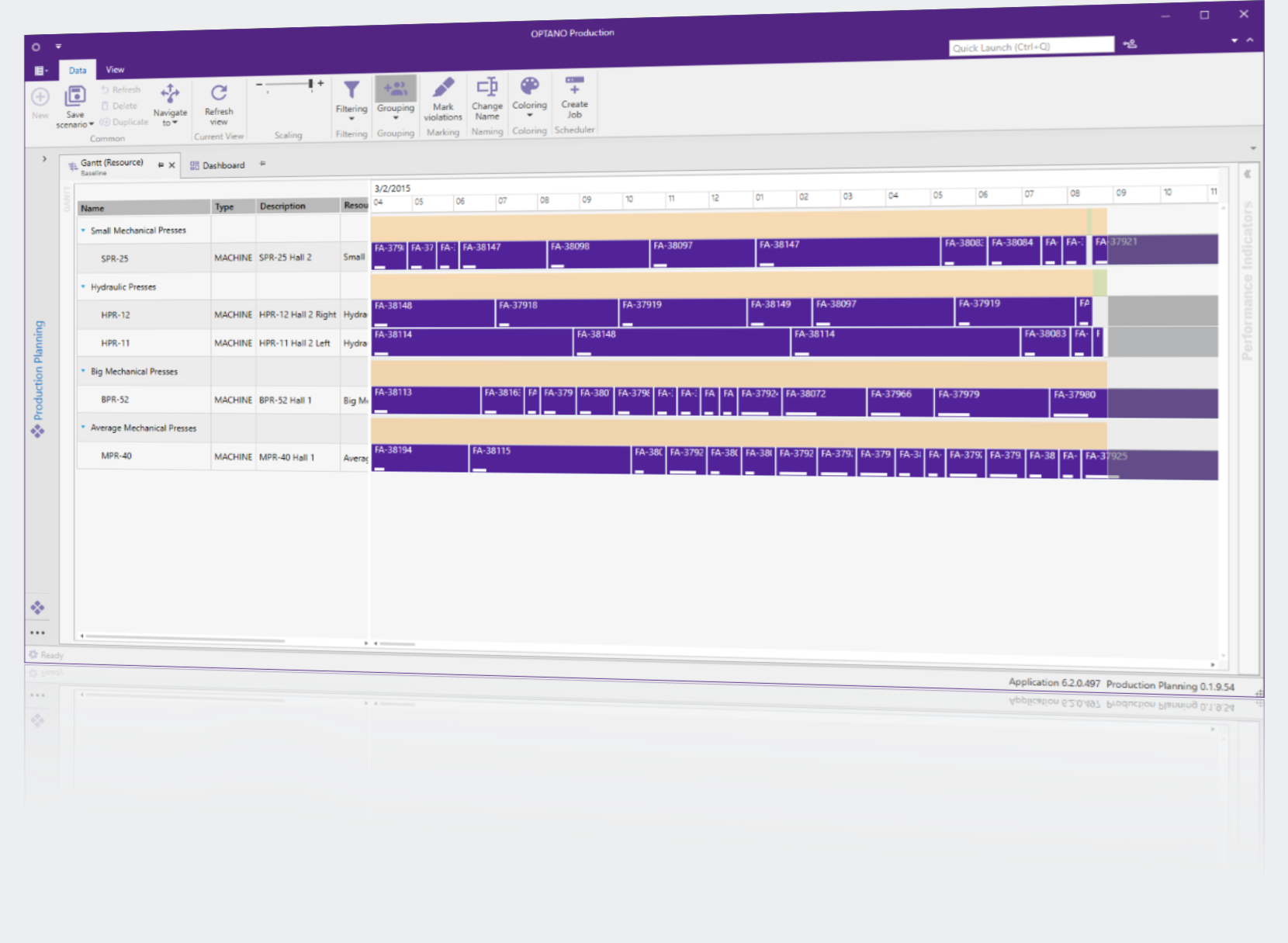

Enhance your delivery reliability

With OPTANO you can noticeably improve your delivery reliability. Scheduled delivery dates are already taken into account when optimizing machine occupancy during planning. Production plans are created which ensure delivery dates. If a delivery date cannot be observed, you will receive advanced notice of this and can take the necessary measures.

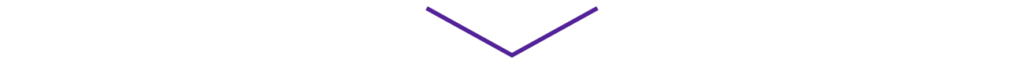

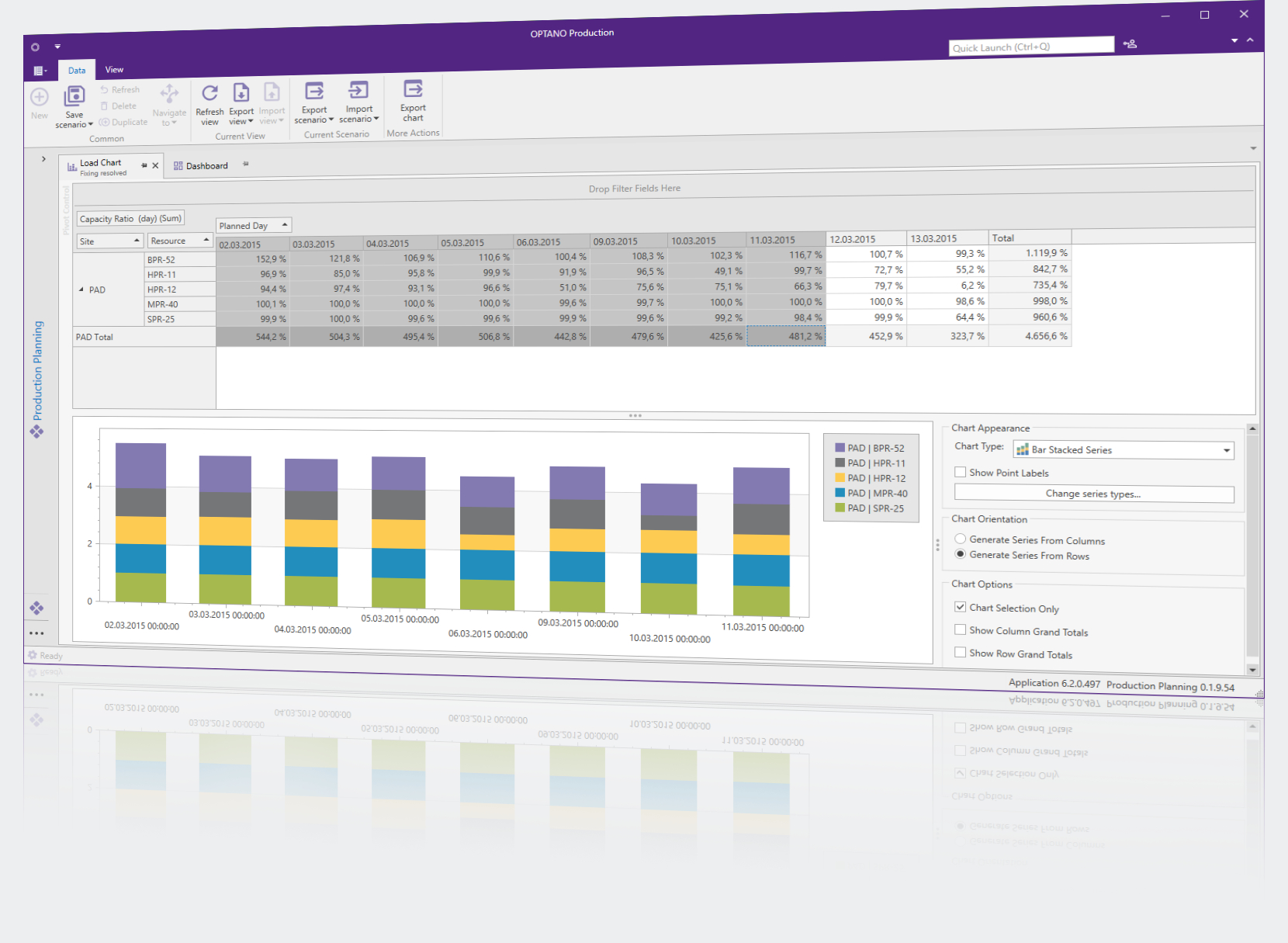

Maximize your machine utilization

By deploying OPTANO you can increase your machine utilization. Automatically levelling production ensures that jobs are evenly distributed. In this way production capacity can be increased considerably. The unleashed potential can then be used to take on more orders and thus increase your turnover. Or you can use it to improve quality or lower costs.

Ensure you have short lead times by minimizing set-up times

The number of set-up procedures can be considerably reduced with OPTANO. If the set-up times and costs are dependent on job sequencing in your company then determining optimal production batches can ensure minimum set-up times. And you save time and resources as a result.

Dr. Sven Flake

OPTANO GmbH

Shorter product life cycles and increasing product individualization mean higher complexity - mathematical optimization and analytics provide sophisticated methods to respond to these changed requirements.

With OPTANO, you benefit from sophisticated technology at the highest level with easy integration into your systems.

Easy to integrate

OPTANO can be integrated flexibly into the existing IT landscape. The safety features use existing user directories (e.g. Active Directory or LDAP) to authenticate users and identify their permissions in OPTANO. In this way, user rights can be maintained and managed automatically. Alternatively, OPTANO comes with its own secure rights management tool.

Data exchange with existing applications is a matter of course. Virtually every OPTANO installation uses data from other systems or transfers planning results to other systems for automated processing. OPTANO gives you the flexibility to make this connection easily.

Rapid Prototyping

The first prototypes are available fast. This enables simplified data extraction and storage as well as an improvement in data quality. As a result, early data validation is feasible.

A single-source solution

With OPTANO you have control over the entire process. Since OPTANO is a 100% in-house development, there is no need to consult with any third parties and your OPTANO solution can be customized to meet your requirements.

Fully localized

Whether it is specific workflows, user navigation or design – OPTANO can be customized to meet your specific requirements. Many features have been tailored to meet the needs of individual industries and are already available on the OPTANO platform. This is why OPTANO gives you the ideal combination of individuality together with proven features and processes.

How can we help you?

You are also welcome to use our contact form. We will then get back to you as soon as possible!

We look forward to talking to you!