Mastering

production

networks

The management of complex production networks is demanding

The management of complex production networks is demanding. Often, the necessary transparency is lacking to coordinate demand and production capacities in such a way that delivery reliability and production costs are in an optimal relationship. Other factors also play a role: not every manufacturing site can produce the same quantity of a product in the same quality at the same prices. Added to this are transport costs, which can quickly skyrocket to the detriment of margins. Another influencing factor is the goal of companies to keep CO2 emissions as low as possible.

So how can a production network be optimized as a whole to ensure efficiency, delivery reliability and sustainability? This is possible with the OPTANO solution for complex production networks. With the help of mathematical decision support and artificial intelligence in user-friendly software, you can identify and leverage hidden potential in production and transport for the sustainable value development of your company. Contact us!

Planning production networks is complex. The OPTANO solution uses mathematical decision support and AI to optimize costs, capacities, transport and sustainability. Contact us!

The OPTANO solution

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

An optimization application is only as good as the data it is based on. Benefit from the simple and user-friendly input options for master and project data in our clear interface with many interfaces and upload options. Individually defined units of measurement and measured variables can be taken into account, as can constraints and secondary conditions.

Examples of input data

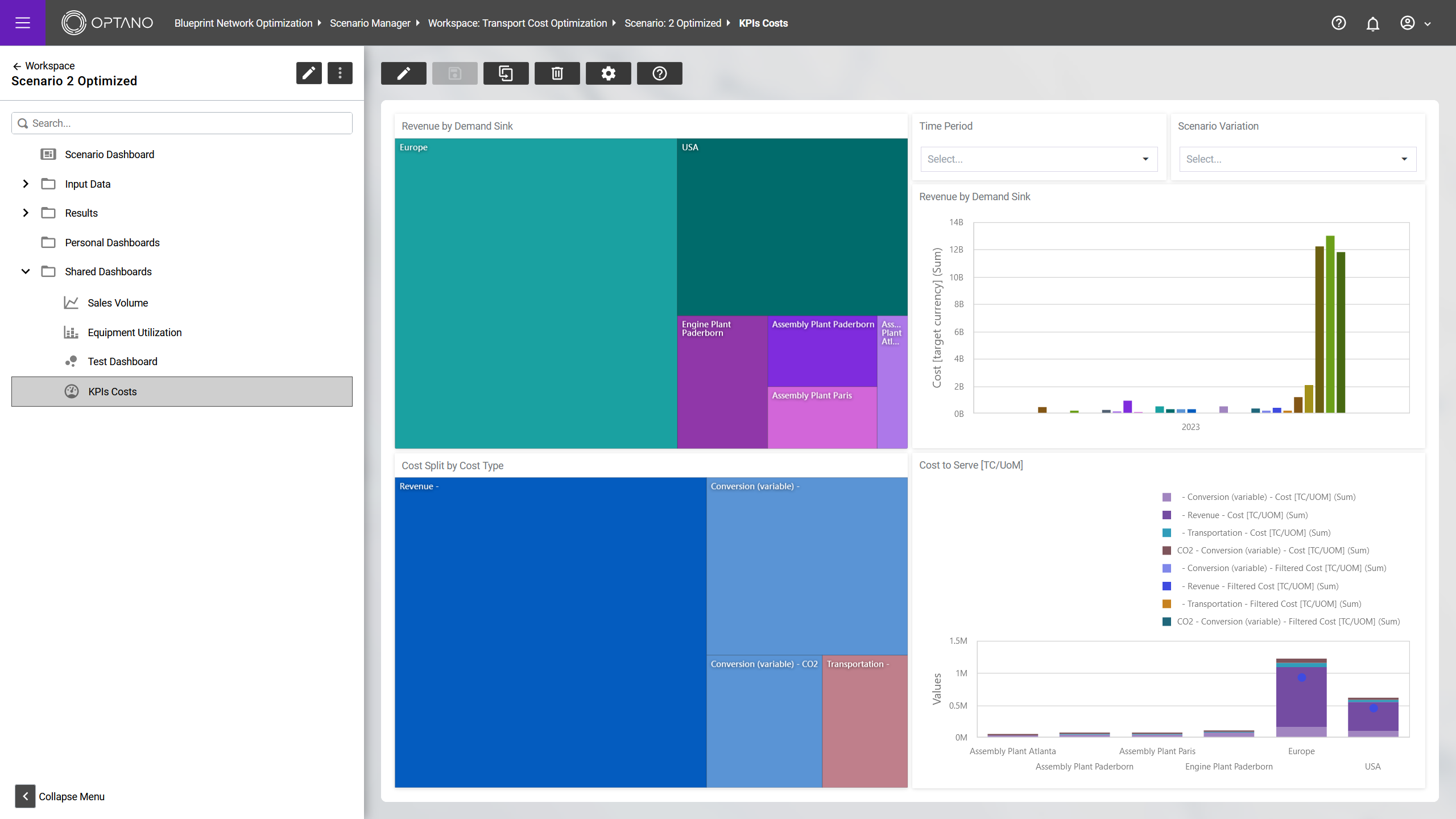

Good preparation turns data into information. Extensive analysis options ensure maximum transparency throughout the entire network, right down to the product level. Interdependencies and influencing factors can be identified and included in decision-making in what-if scenarios.

Examples of analysis information

Long-term decisions require foresight. By optimizing your network at the strategic level, you set the course for future and lasting success – be it in making sustainable investment decisions or implementing different procurement strategies.

Examples of strategic planning issues

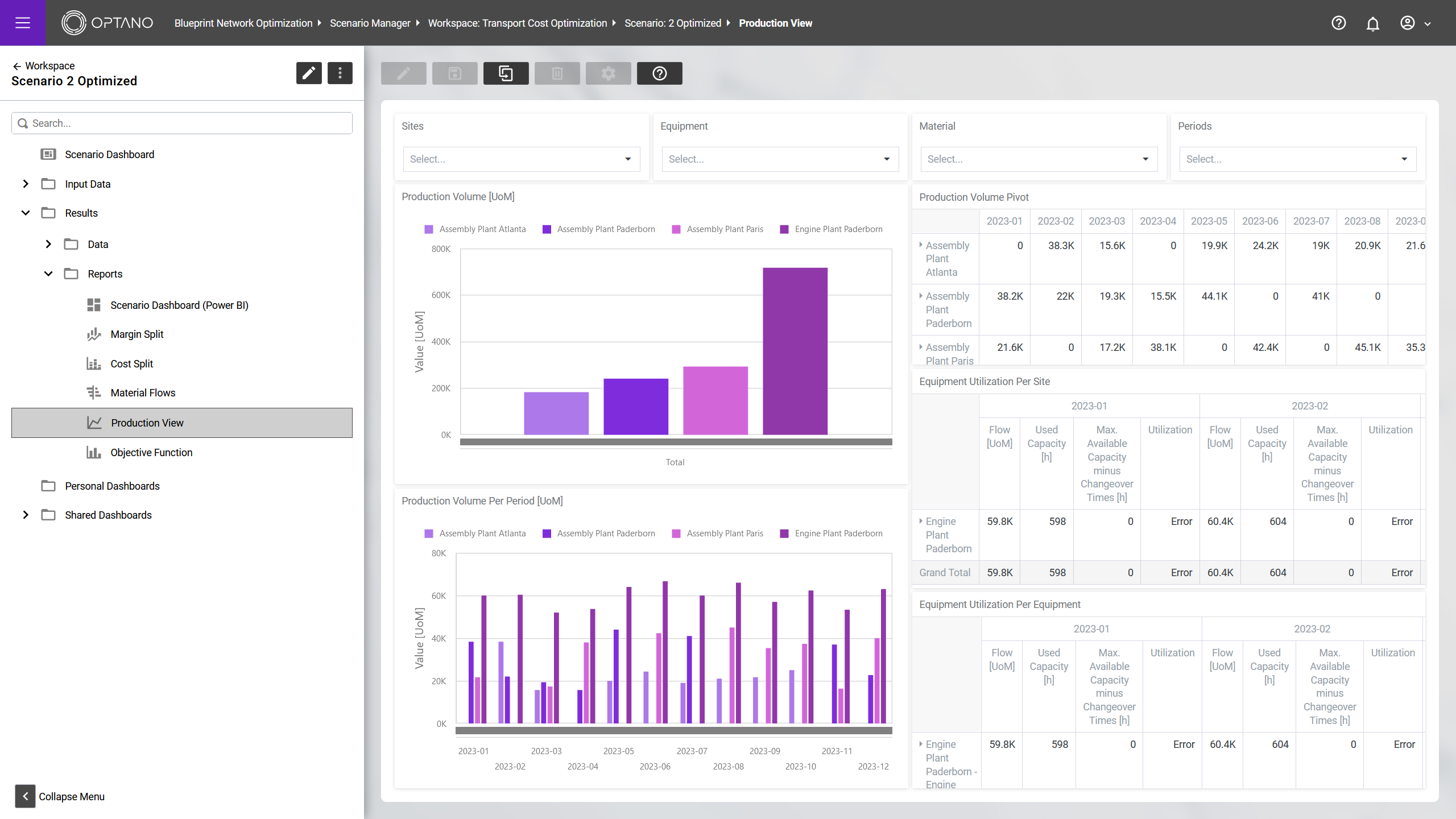

Always keep an eye on your network. At the tactical level, you can distribute real and anticipated demand among the available production capacities and thus ensure maximum capacity utilization at consistently low costs. Uncover hidden optimization potential in production and transport and optimize your supply portfolio with a single tool.

Examples of tactical planning issues

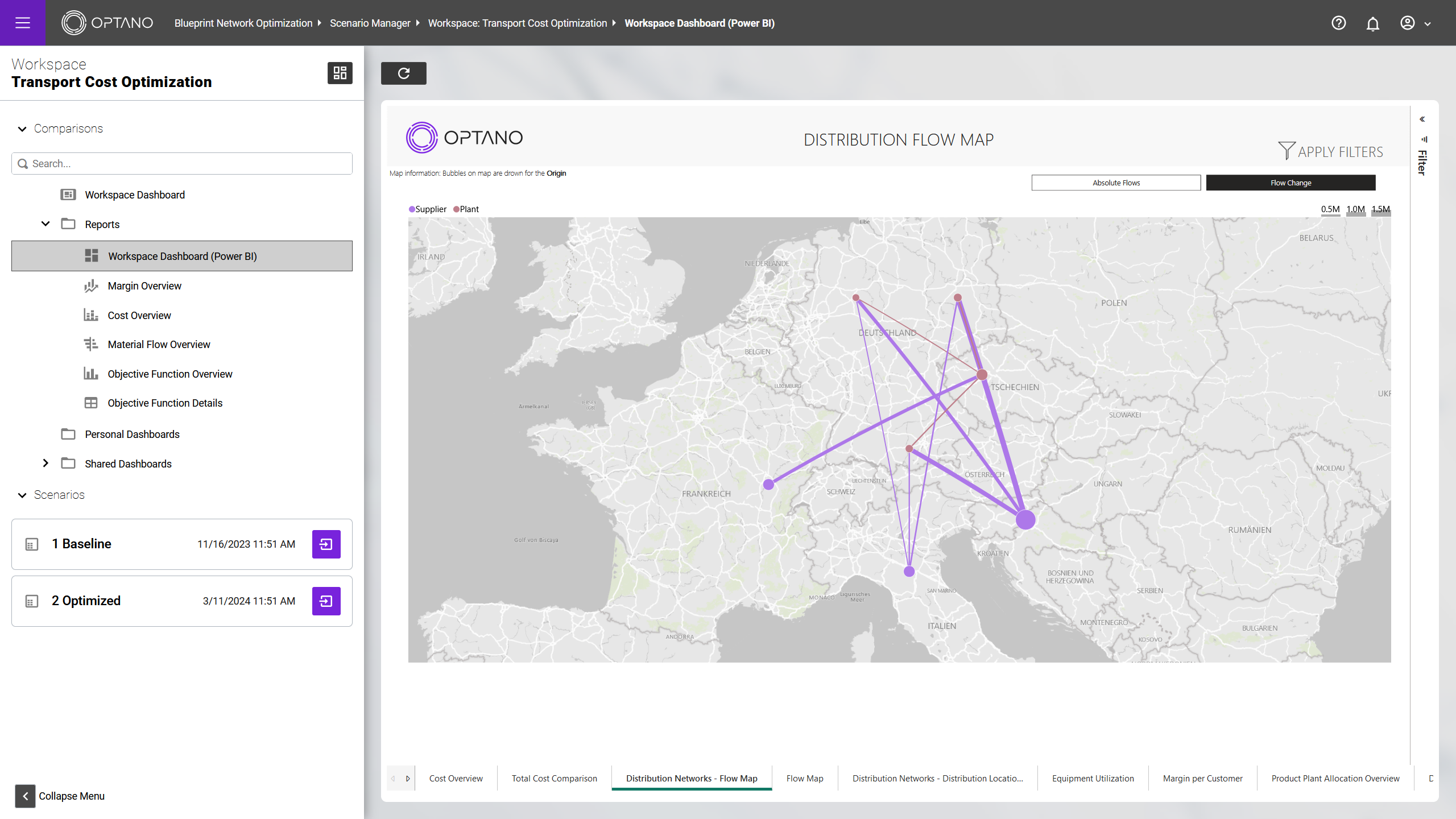

Good reporting is important to better understand and share information. Configure individual reporting with just a few clicks and benefit from many graphical preparation options through interfaces to Excel, Power-BI and Tableau.

Reporting examples

Reduction of operating costs across locations.

Systematic margin increase across the portfolio

Increase in customer satisfaction through optimal availability of goods

Reduction of CO2 emissions with simultaneous cost efficiency

Transparency in

the entire network

Simple and intuitive operation

Subsequent

investment decisions

More resilience

in the overall network

How can we help you?

You are also welcome to use our contact form. We will then get back to you as soon as possible!

We look forward to talking to you!