Optimal planning for

the mining industry

Getting the best out of your resources!

When we think of mining, we often think of large coal mines – and these will gradually disappear with increasing decarbonization. Yet mining encompasses a lot more than the extraction of coal: (quartz) sand, gravel, salt, limestone and many others are also extracted through mining! Another aspect which tends to be overlooked here is that the production of green energy also consumes raw materials of this kind – for example in the production of wind turbines and photovoltaic systems.

In mining, too, it is literally a matter of getting the most out of your resources. This is now possible with digitization and the use of mathematical optimization.

Using mathematical optimization to achieve optimal

use of resources and maximum efficiency.

Supply Chain Planning

OPTANO always finds the best decisions to help you manage the fluctuating supply-and-demand dynamics which are inherent in the mining industry .

Logistics planning

Logistics planning is a major challenge in mining. With OPTANO you can always find the best solution to your specific logistics challenges.

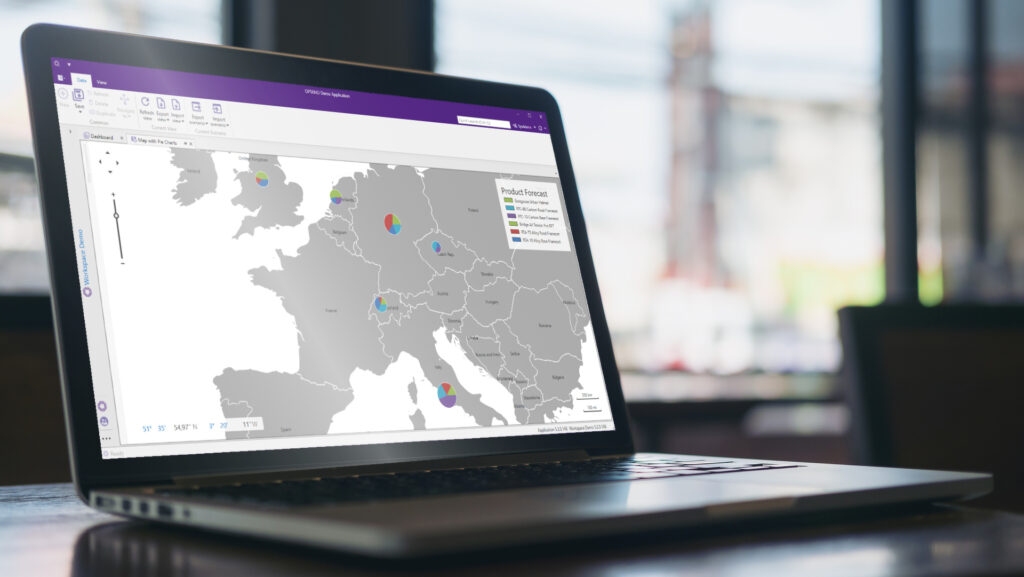

End-to-End Network Planning

End-to-end planning with OPTANO lets you to optimize both your outgoing and incoming supply chain – giving you a clear overview of all the changing factors.

Employee Capacity Planning

Employees are a valuable asset. With OPTANO you can instantly create employee schedules which are both cost-efficient and employee-friendly. Here your employees’ individual skills and qualifications as well as their worktime requests are taken into account.

Dr. Dominik Hollmann

OPTANO GmbH

By deploying mathematical

optimization we can make more

efficient use of our resources. Whether these are raw materials, load or warehouse capacities or the use of energy - nothing should go to waste.

How can we help you?

You are also welcome to use our contact form. We will then get back to you as soon as possible!

We look forward to talking to you!