Efficient warehouse management saves time, money and resources. With digital inventory planning software, you can keep track of your stocks at all times, automate processes and avoid overstocking or understocking. This allows you to reduce your storage costs and improve your ability to deliver at the same time. Find out how modern tools can digitally transform your warehouse.

OPTANO in warehouse management - a customized solution

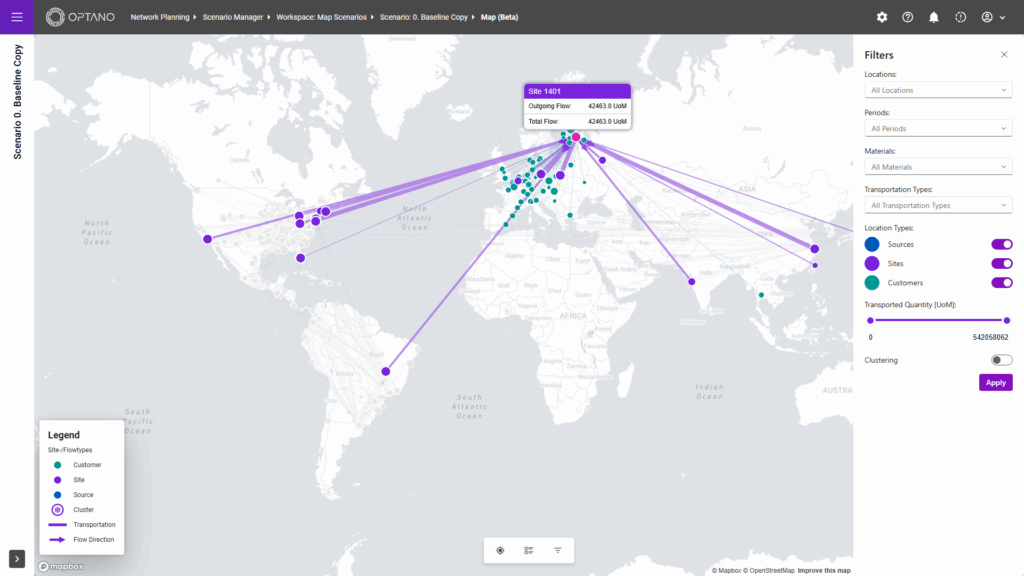

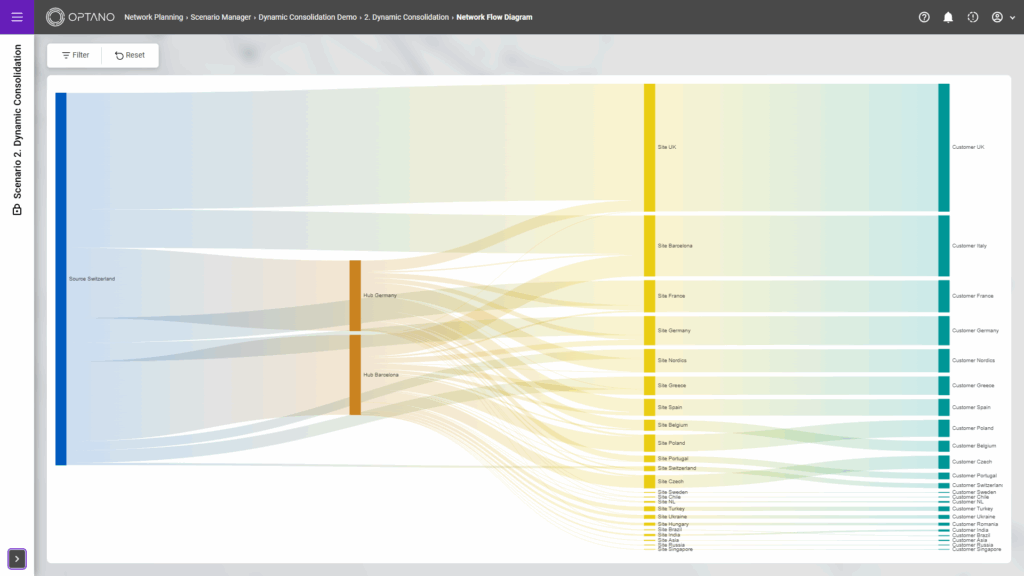

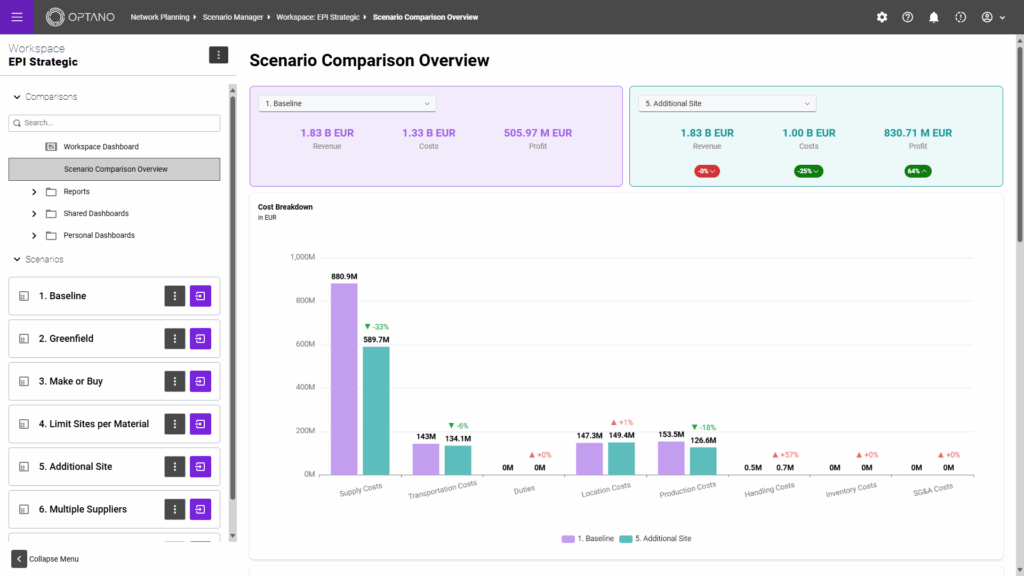

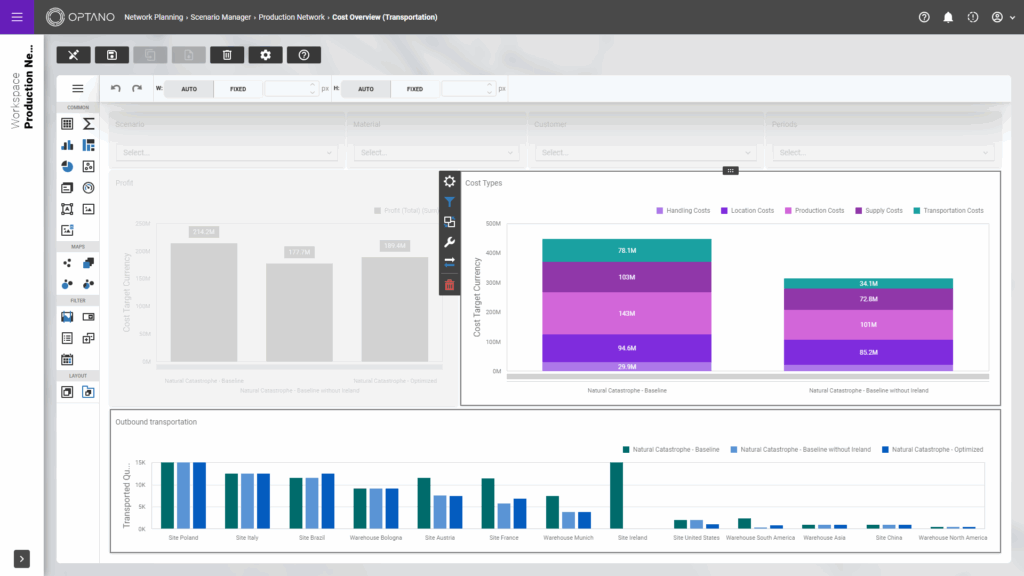

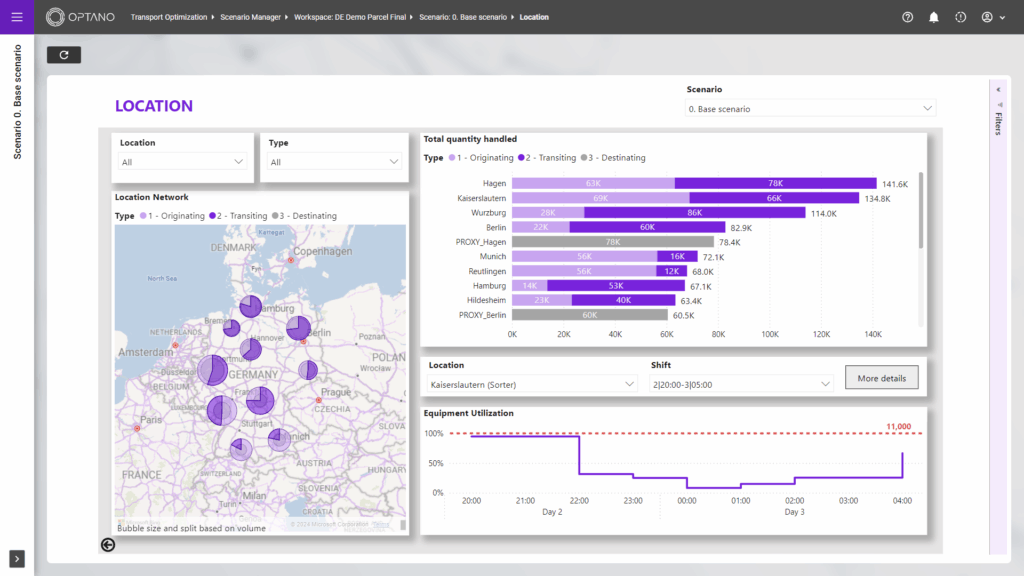

Scenario comparison

OPTANO enables the optimization and comparison of different warehouse strategies, for example with regard to seasonal fluctuations, delivery delays or changing demand profiles. The scenario comparison illustrates the effects of different parameters on stock levels, service levels and costs. This allows well-founded decisions to be made and risks in warehouse planning to be minimized in the long term.

Safety stocks based on distribution functions

OPTANO calculates safety stocks using statistical distribution models. As a result, uncertainties regarding demand and delivery times are systematically and precisely taken into account. The solution supports companies in minimizing excess stock while ensuring reliable delivery capability - as the basis for stable, data-based warehousing.

Ordering policies

With OPTANO, company-specific ordering guidelines can be reliably defined and controlled, including minimum stock levels, ordering cycles and dynamic replenishment rules. The software integrates current demand forecasts, delivery times and storage costs into the decision-making process to ensure efficient and optimal ordering processes. In this way, demand-oriented and efficient order planning is guaranteed.

Categorization

OPTANO allows items to be classified according to ABC, XYZ or individual criteria. This allows warehouse strategies to be specifically adapted to different product groups, for example through graduated safety stocks or specific order specifications. Categorization ensures greater transparency and supports the strategic management of warehouse resources.

Service level and fill rate

OPTANO makes it possible to precisely analyze and optimize service levels and fill rates for individual items. The software makes it clear how warehouse decisions influence delivery capability and supports companies in efficiently achieving defined target values. This ensures constant availability of all items, which helps to improve customer satisfaction while optimizing storage costs.

Inventory Target Tracker

The OPTANO Inventory Target Tracker offers continuous monitoring of defined stock levels. Potential deviations are identified promptly and targeted recommendations for optimization are provided. This ensures transparent tracking of inventory targets - regardless of strategic framework conditions, seasonal fluctuations or operational requirements.

Our industry expertise in warehouse management

Advantages at a glance

Permanently reduce storage costs

Automated reordering

Plan warehouse structure strategically

Optimize safety stocks

Increase liquidity

Recognize bottlenecks at an early stage

Targeted increase in service level

Improve risk modeling